2020-01-28

Please leave it to the installation! A diamond-shaped wire mesh shop that also performs installation work on site

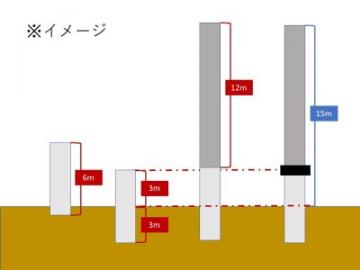

Kyowa Steel Industry Co., Ltd. manufactures and sells diamond wire mesh in Higashi Osaka. In the case of highly specialized projects such as large cases, not only manufacturing but also on-site installation work (suburbs of Osaka) is performed. Kyowa can design and manufacture all kinds of diamond-shaped wire mesh depending on the wire material, thickness, mesh size and dimensions. Requests for small lots of about 1 square meter are OK. Requests for lengths and heights to be used for fences and walls of buildings are also OK. Anyway, it is a factory that can do anything related to diamond wire mesh. Therefore, Kyowa Steel's wire mesh is very active in every place and every use. There is a wide variety of things from ordinary homes and stores to booths for exhibitions and large public works. Until the last time, we talked about planning and manufacturing interiors and furniture that combine different materials and wire mesh as an initiative at KENTEN that challenged with “Team Higashi Osaka Open Innovation”, but this time Mr. Kyowa Steel received Was taught about public works. The diamond-shaped wire mesh is made by weaving the wire, so it has a very large shock absorbing power and is durable. Rhombus wire mesh is also used for access prevention fences and safety fences beside the Shinkansen tracks, as well as rockfall and snowfall prevention fences. In this way, specialty is required for construction, especially in cases where it is used to protect the safety of our lives. Especially if it is a widespread construction or short delivery time. The construction scheduled to start this month is to replace a ball-proof net at a certain park in Osaka City. It will be a wide-ranging replacement to raise the height of the originally 12m net to 15m. It starts from surveying because the ground has a slope. Remove all existing concrete pillars, dig holes and insert new pillars. Then, when the pillars stand, we will wire and finally wire the wire, but its length is 170m! I guessed it was a very large project, and it seems to be a relatively simple one and it will be completed in a month. It is very encouraging that factories that go from manufacturing wire mesh and know everything about wire mesh will be able to receive everything from construction to construction. Will next month's research be completed? In addition, we would like you to tell us during and after construction! Thank you Kyowa. ★ Kenten2020, where everyone at Kyowa Kogyo is also a member of “Team Higashi Osaka Open Innovation,” will be held at INTEX Osaka on June 11-12. Please come to see me. ▶▶▶ KENTEN2020 page https://www.ken-ten.jp/

Categories

Latest Posts

2020-02-26

Not just a fence! New use cases of wire mesh released!

2020-02-12

Ball net rebuilding construction, I came here in 2 weeks

2020-01-28

Please leave it to the installation! A diamond-shaped wire mesh shop that also performs installation work on site

2020-01-17

Higashi-Osaka Town Factory Proposes Workspace, Kids Room, and Cafe Space Higashi-Osaka Town Factory Proposes Workspace, Kids Room, and Cafe

2019-12-20

KENTEN2020 will release the finished product from Team Higashi Osaka!

Map

5-chōme-8-11 Mizuhai, Higashiosaka, Osaka 578-0921, Japan

072-966-8331